Car Bottom Furnace

Car Bottom Furnace (CBF) – an innovative heat treatment solution designed for efficient and precise thermal processing in industrial applications. The CBF boasts unique characteristics and numerous advantages, making it an excellent choice for both the first baking and re-baking processes.

CAR BOTTOM FURNACE (CBF) CHARACTERISTICS

| CBF Details | Parameter |

| Baking time | ~450h(first baking) ~90h(re-baking) |

| Products | carbon blocks, graphite electrodes and nipples |

| Dimensions | 19000*6500*5000(Approx.) |

| Baking temperature | 950℃ |

| Effective volume | 275m³ |

| Fuel | Natural Gas |

| temperature difference | ≤2.5℃ |

| Maximum Load Capacity | ~300t |

ADVANTAGES

1. Reduced baking time

CBF has good sealing performance and the temperature in the furnace rises quickly. And use a water spray device to force cooling. It is beneficial to shorten the baking cycle and improve production efficiency.

2. High consistency of temperature in a furnace

During the baking process, the flue gas in the furnace is always in a state of circulating convection due to the high-temperature fan on the top of the furnace, so the temperature distribution throughout the furnace always remains relatively uniform.

3. Better quality of baked products

During heating, the product is loaded into a saggar and heated indirectly, so that all parts are heated evenly. During cooling, the water spray device is helpful in relieving the internal stress of the baked product. Therefore, the baking yield is high and the product quality is uniform.

4. Highly automated control system

Advanced burner system and automatic temperature control measures are adopted, and fuel supply is adjusted through reliable actuators to ensure heating and cooling in accordance with the temperature curve.

5. Universal for first and re-baking

CBF takes into account both first baking and re-baking. During re-baking, the product does not need filler protection when it is loaded into the saggar, so the time required for secondary roasting can be greatly shortened.

6. Adjustable temperature curve

Each CBF can be set to a different temperature curve for each operation, providing great production flexibility.

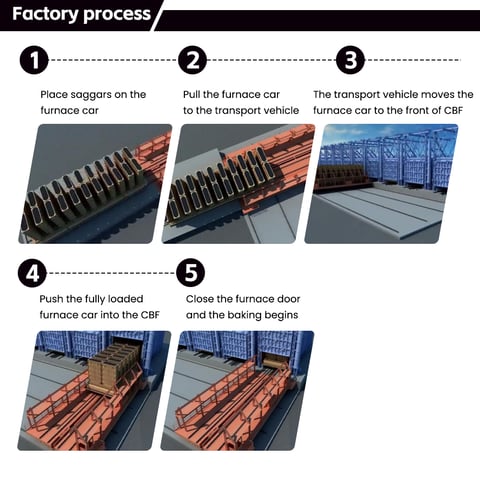

7. Mechanized loading and unloading process

The loading and unloading of products is carried out at special loading and unloading stations, which improves working conditions and reduces labor intensity.

8. Environmentally friendly

The volatile matter produced during baking leads to the incinerator for combustion. The heat from the incineration can be utilized by setting up a waste heat boiler, and the production environment outside the furnace is clean.