Table of Contents

Reaching New Heights: The Ultimate Guide to Stacking Cranes in Action

The Basics of Stacking Cranes

Stacking cranes are essential heavy machinery used in construction and industrial settings for lifting and moving heavy materials and objects. These cranes are designed to reach impressive heights, making them an indispensable tool for projects that require vertical movement of materials. In this ultimate guide, we will explore the various aspects of stacking cranes in action and how they contribute to the success of construction projects.

Understanding Different Types of Stacking Cranes

Stacking cranes come in various types, each designed for specific tasks and environments. The most common types include tower cranes, telescopic cranes, crawler cranes, and overhead cranes. Tower cranes are often seen on tall construction sites, while telescopic cranes are popular for their mobility and versatility. Crawler cranes are known for their stability on uneven surfaces, and overhead cranes are commonly used in warehouses and manufacturing facilities. Each type offers unique advantages depending on the project requirements.

The Importance of Safety Measures

Operating stacking cranes requires strict adherence to safety protocols to ensure the well-being of workers and the integrity of the machinery. Safety measures include regular inspections, proper training for operators, and the use of safety equipment such as harnesses and helmets. Additionally, establishing clear communication channels and maintaining a safe distance from the crane during operation are crucial for preventing accidents. Safety should always be the top priority when working with stacking cranes.

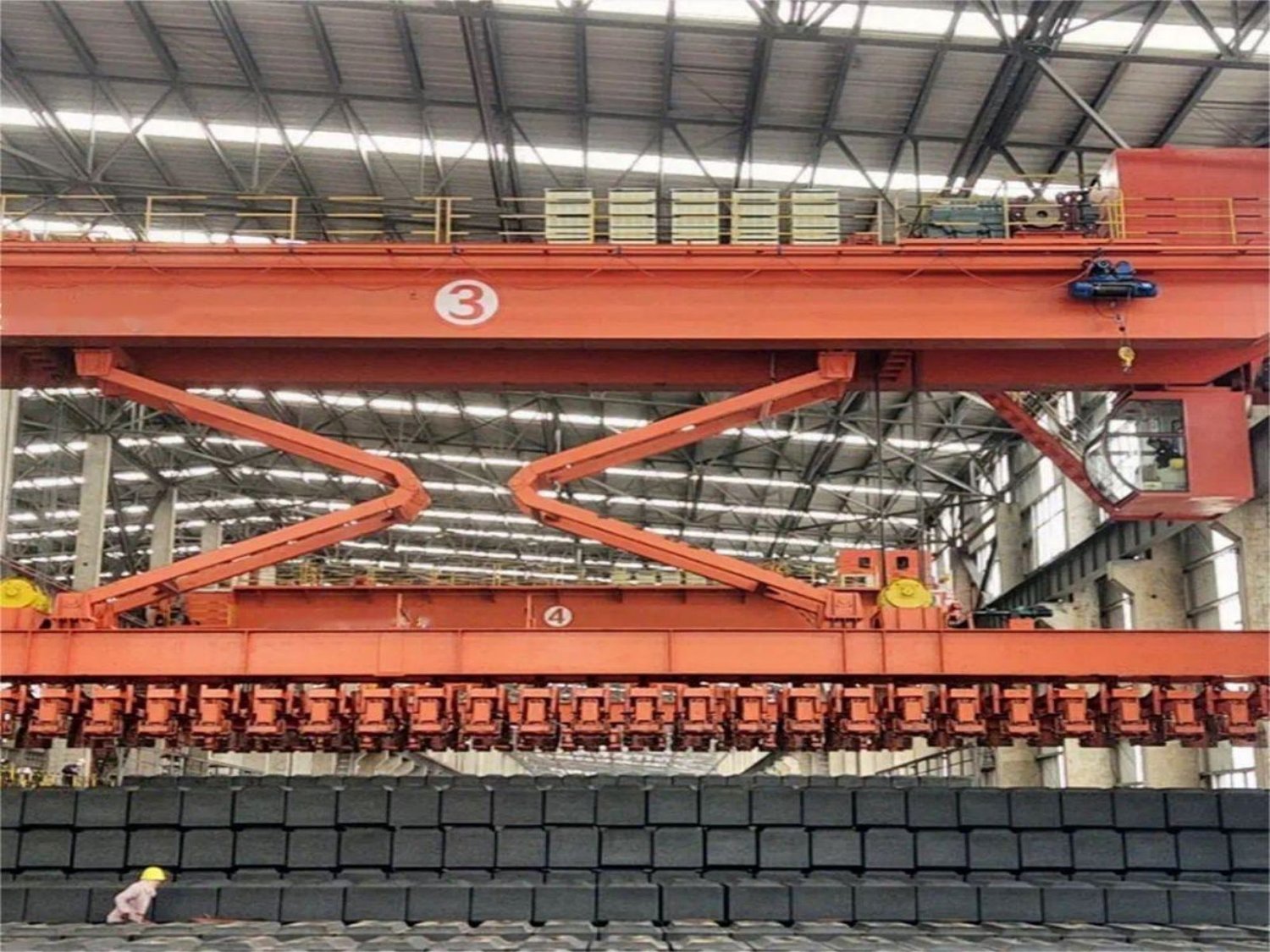

Key Components of Stacking Cranes

Stacking cranes consist of several important components that work together to achieve efficient lifting and moving operations. The main components include the boom, jib, mast, counterweights, and the control system. The boom is the horizontal arm that extends from the crane's base, while the jib is an additional arm that allows for increased maneuverability. The mast provides stability and height, and counterweights balance the load. The control system enables precise movements and ensures the crane operates smoothly and safely.

Factors Influencing Crane Height

Stacking cranes are renowned for their ability to reach impressive heights. Several factors influence the maximum height a crane can achieve, including the crane's type, boom length, and the counterbalance applied. Tower cranes, for example, can reach greater heights due to their tall mast and the ability to add additional sections. The boom length also plays a crucial role, as longer booms allow for higher lifting capacities and greater reach. Proper counterbalance is essential to maintain stability at elevated heights.

Applications of Stacking Cranes

Stacking cranes find applications in various industries and settings. In the construction industry, they are used for lifting heavy building materials, such as steel beams and concrete panels, to great heights. Stacking cranes also play a vital role in the shipping industry, where they are employed in ports for loading and unloading cargo containers from ships. Additionally, stacking cranes are utilized in manufacturing facilities, warehouses, and even in the installation of large-scale artworks and sculptures.

Advanced Features and Technologies

With technological advancements, stacking cranes have become more efficient, safer, and easier to operate. Some modern cranes feature advanced automation systems that allow for remote control operation, reducing the risk to operators. Anti-collision systems are also implemented to prevent accidents when multiple cranes are working in close proximity. Additionally, sensors and cameras provide real-time feedback to operators, enhancing their situational awareness and improving overall safety and productivity.

Maintenance and Upkeep of Stacking Cranes

Regular maintenance and upkeep are crucial for ensuring the longevity and optimal performance of stacking cranes. This includes routine inspections, lubrication of moving parts, and checking the integrity of safety mechanisms. Any signs of wear and tear or malfunctions should be addressed immediately to prevent accidents or breakdowns during operation. A well-maintained crane not only ensures safety but also minimizes downtime and maximizes productivity on construction sites or other industrial projects.

Training and Certification for Stacking Crane Operators

Operating stacking cranes requires specialized skills and knowledge. Crane operators must undergo comprehensive training programs to understand the principles of crane operation, safety protocols, and equipment maintenance. Additionally, operators must obtain the necessary certifications to demonstrate their competence in operating stacking cranes. Ongoing training and professional development are vital for operators to stay updated with industry standards and best practices.

The Future of Stacking Cranes

As technology continues to advance, the future of stacking cranes looks promising. Innovations such as autonomous operation, enhanced safety features, and improved efficiency are expected to revolutionize the industry. The integration of artificial intelligence and machine learning may further optimize crane operations, leading to increased productivity and reduced risks. As construction and industrial projects continue to reach new heights, stacking cranes will remain an essential tool in shaping our modern world.